From Fiction to Real Engineering

When we first saw Tony Stark building his suit in Iron Man, it seemed like pure science fiction: holographic design, smart materials, and virtual flight testing. Yet that same combination — digital design, advanced simulation, and mechanical precision — has become part of the daily workflow for thousands of engineers worldwide.

At the heart of this technological revolution is SOLIDWORKS, one of the most trusted and widely used 3D CAD platforms on the market. For over 25 years, SOLIDWORKS has been driving innovation in mechanical, biomedical, automotive, aerospace, and manufacturing engineering. Its ecosystem enables teams to conceptualize, create, validate, and manufacture products with a level of precision that once seemed impossible.

The result is a new era where imagination and engineering come together — and ideas that once existed only on the big screen are now brought to life through the power of 3D design.

Engineering with Purpose: 3D Design for the Real World

Whether designing a bionic prosthesis, a turbine, or a precision part for the aerospace industry, engineers need a tool that gives them full control over the design process.

That’s where SOLIDWORKS 2026 comes in — taking 3D modeling to the next level with:

- Complex part and assembly design, with intuitive, accurate tools.

- Integrated stress analysis and motion simulation, to validate performance before production.

- Cost estimation and feasibility checks, helping reduce time and optimize materials.

- Data management and version control, ensuring every team member works from the same source without errors or duplication.

These features make SOLIDWORKS much more than a design program: it’s a complete engineering platform where creativity meets technical precision. In this environment, design evolves from a visual representation into real engineering ready for manufacturing.

World-Changing Projects: The Real Impact of SOLIDWORKS

Across the globe, innovative projects are showcasing SOLIDWORKS’ role in developing biomedical devices, customized prosthetics, and high-performance industrial solutions.

Initiatives like the Victoria Hand Project and Mitt Wearables use SOLIDWORKS to design accessible, functional prosthetics with full structural validation before manufacturing.

Thanks to its simulation tools, engineers can analyze each component’s behavior under different use conditions, ensuring safety and durability.

According to the official SOLIDWORKS blog and partners like TriMech and Javelin Technologies, these 3D CAD solutions help reduce costs, shorten development cycles, and improve product quality through advanced simulation and additive manufacturing.

Similarly, companies in the automotive and aerospace industries are leveraging SOLIDWORKS 2026 to integrate AI-powered predictive design, optimizing performance before a single physical prototype is built.

Collaborative Innovation: When Design and Engineering Speak the Same Language

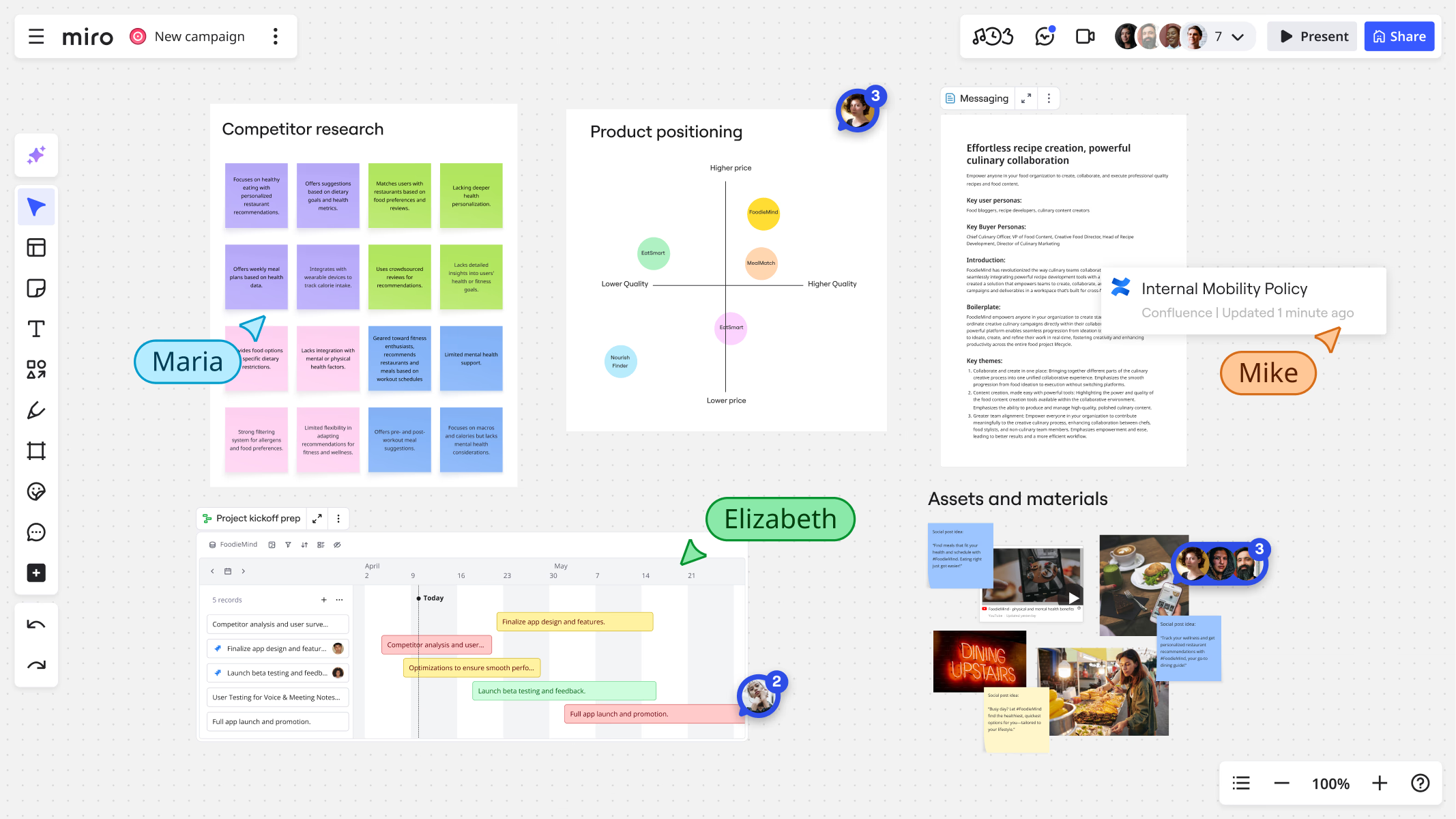

One of SOLIDWORKS’ greatest advantages is enabling multiple disciplines — mechanical, electronic, manufacturing, or biomedical — to collaborate within a unified environment.

Its integrated data management tools allow revision control, 3D model sharing, and real-time validation — all essential for cross-functional teams.

This not only minimizes errors but also speeds up decision-making and enhances technical communication.

The result is a faster, more transparent workflow, where innovation isn’t slowed down by bureaucracy or outdated versions. Every stage — from concept to validation — happens within a cloud-connected digital ecosystem, ready for the challenges of Industry 4.0.

The Engineering of the Future Is Designed in 3D

The future of engineering is already here — and it’s being designed with SOLIDWORKS 2026.

With each new release, the platform strengthens its position as the bridge between creativity, technical precision, and efficiency.

Sources:

Frequently Asked Questions about SOLIDWORKS 2026

What’s new in SOLIDWORKS 2026 compared to previous versions?

It features enhanced advanced simulation, cloud integration, AI-powered predictive analysis, and a smoother environment for cross-disciplinary collaboration.

Which industries use SOLIDWORKS?

SOLIDWORKS is widely used in mechanical, biomedical, automotive, aerospace, electronics, and manufacturing engineering. Its flexibility makes it ideal for both startups and large corporations.

Do I need advanced knowledge to use SOLIDWORKS?

Not necessarily. The platform features an intuitive interface and progressive learning curve, supported by official documentation, tutorials, and certifications.

Can SOLIDWORKS integrate with other simulation or manufacturing tools?

Yes. It integrates with structural analysis, fluid simulation, 3D printing, and additive manufacturing tools, as well as project management and PDM platforms.